Capabilities

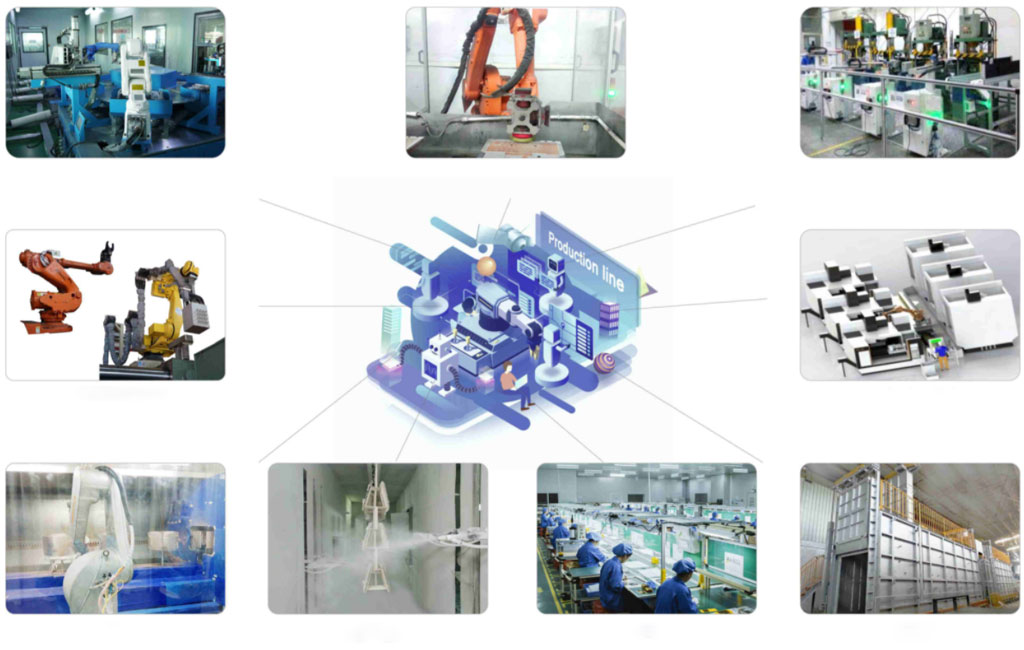

The group has 7 subsidiaries and production bases in Guangdong/Hunan/Chongqing, which can fully cooperate with customers in different regions to serve nearby customers. It has a production and service team of more than 500 people, and has 13 invention patents and 39 pieces utility model patents.Die casting, mold manufacturing, cnc machining, 3d printing are the four key business segments of the company.

Precision Die Casting Capabilities

Dongguan Pintejin Group introduces equipment imported from Japan/Germany and provides customers with comprehensive technical support

Automatic Die Casting Line

- The Manipulator Automatically Removes The Front

- Automatic Grinding

- Automatic Drilling Machine

- Die Casting Automatic Pickup Spray

- CNC Automatic Pick And Place

- Automatic Fuel Injection

- Automatic Dusting

- Automatic Assembly

- T6 Heat Treatment

We providing quality, in-house automatic die casting services.

Type of Machines CNC Machining Center Wire-cut E.D.M CNC milling machine Lathe Drilling machine Grinding machine Sand-wheel machine Shaper machine Total 91

Molds 3000T 2000T 800T 650T Mold Capacity/Month 0.5 set 1 set 35 set 35 set Molding/Days 90 day 70 day 40 day 35 day

Communicate

DFM Meeting

Molds Machining

Precision Machining

Finished Mold

Robot Pick Up

Material Stock

Die Casting

Manufacturing

CNC Machining

CNC Center

Automatic Machining

Finished Product

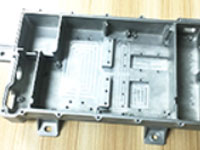

Precision Castings

New Energy Parts

Remove Front

Single Packaging

Post-Processing Line

Anodizing

Shipping