Aluminum Die Casting

Aluminum Die Casting is an aluminum alloy die casting that is formed by applying high pressure to the molten metal in the inner cavity of the mold, that is, using a die-casting machine. Aluminum parts or aluminum alloy parts with limited shapes and sizes. Since metal aluminum and aluminum alloys have good fluidity and plasticity, and the casting process is cast in a pressure die casting machine, aluminum die-casting parts can be made of various More complex shapes can also be made with high precision and finish, which greatly reduces the machining amount of castings and the casting allowance of metal aluminum or aluminum alloy, which not only saves electricity, metal materials, but also greatly saves labor cost; while aluminum and aluminum alloys have excellent thermal conductivity, small specific gravity and high machinability; thus aluminum die castings are widely used in automobile manufacturing, internal combustion engine production, motorcycle manufacturing, motor manufacturing, oil pump manufacturing, transmission machinery Manufacturing, precision instruments, landscaping, power construction, architectural decoration and other industries.

But it has a set of high-tech core pulling, cooling and other systems. In general, the material is sent to the cavity to be “injected” through a centralized inlet to form the part. Aluminum die-casting parts have different names in different places, such as aluminum die-casting parts, die-casting aluminum parts, die-casting aluminum parts, die-casting aluminum, aluminum die-casting parts, aluminum alloy die-casting parts, etc.

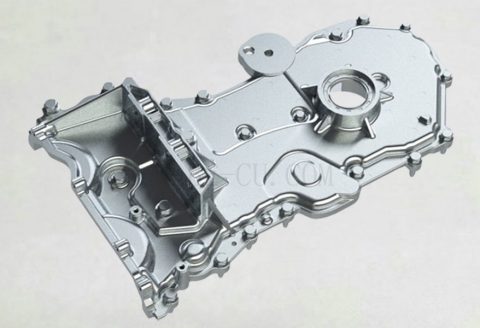

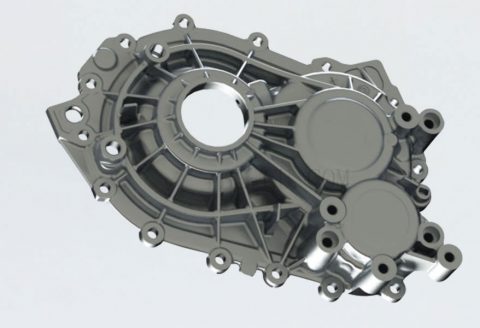

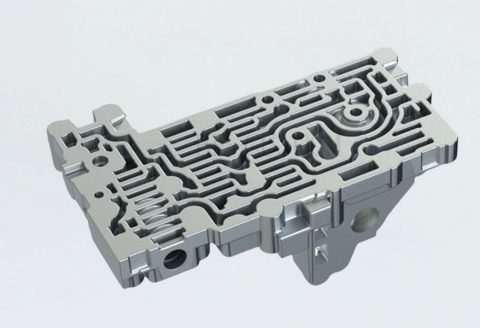

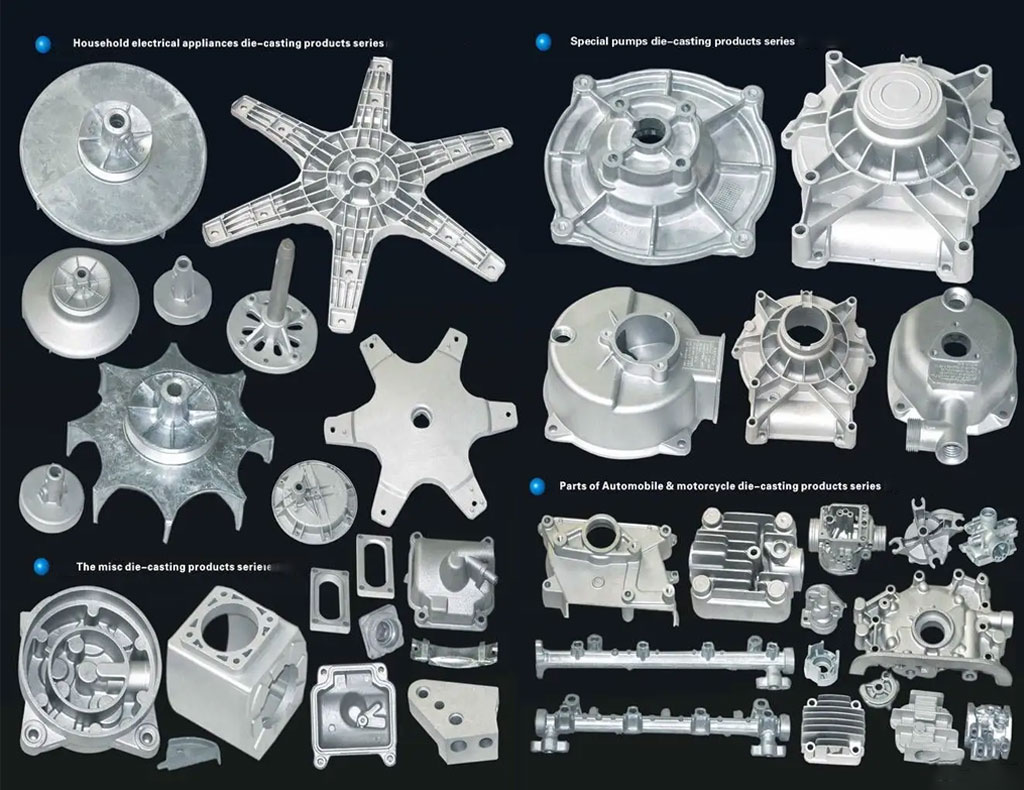

Aluminum die-casting parts can be manufactured as aluminum die-casting auto parts, aluminum die-casting automobile engine pipe fittings, aluminum die-casting engine cylinder, aluminum die-casting gasoline engine cylinder head, aluminum die-casting valve rocker arm, aluminum die-casting valve seat, aluminum die-casting power accessories, aluminum die-casting motor End caps, aluminum die-casting housings, aluminum die-casting pump housings, aluminum die-casting building accessories, aluminum die-casting decorative accessories, aluminum die-casting guardrail accessories, aluminum die-casting aluminum wheels and other parts.

Why Often Using Aluminum For Die Casting Material?

Aluminum sees frequent use in die castings for producing lightweight, intricate designs.Its performance advantages in the die casting process are as follows:

- It carries high strength and less density. Thus making it easier for the die casting shop owners.

- Since aluminum is corrosion-resistant. Therefore it is ideal for creating parts for the marine industry.

- Aluminum retains all its main properties. These are ductility, softness, and strength even at the lowest temperatures.

- It offers the effective machinability required for die casting and cnc machining. Due to its soft nature, aluminum gets cut and requires less power to get machined.

- Aluminum as a material is recyclable.

If product teams choose to die casting part using aluminum, they can trust they’re choosing a strong, conductive, and corrosion-resistant material. Cast aluminum alloys are less expensive to produce due to their low melting point and can produce a broader range of shapes thanks to the flexibility of molds. But they tend to have lower tensile strengths than wrought alloys, aren’t as easy to machine and are more hard-wearing on cutting tools.

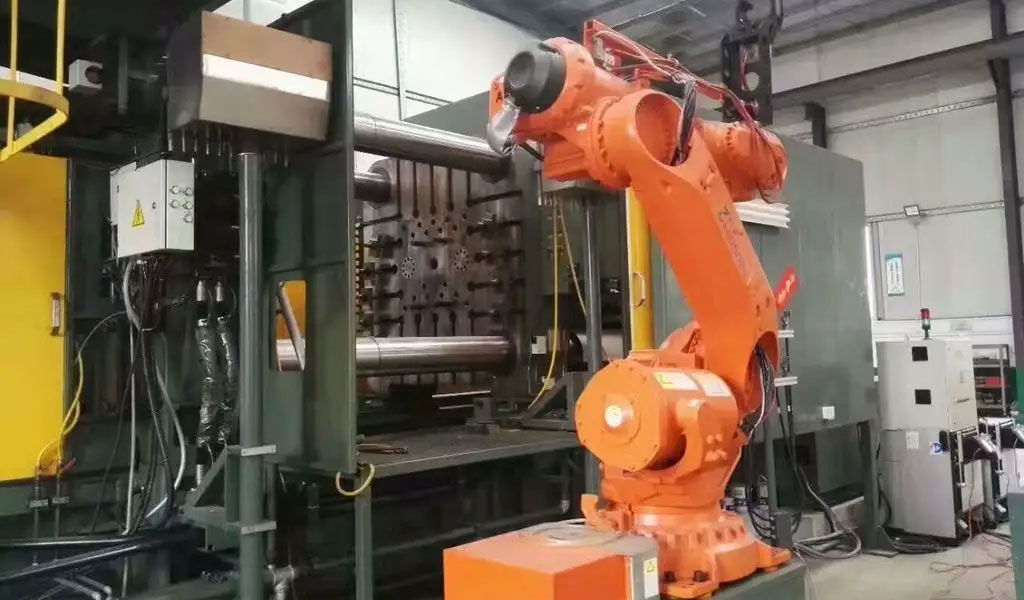

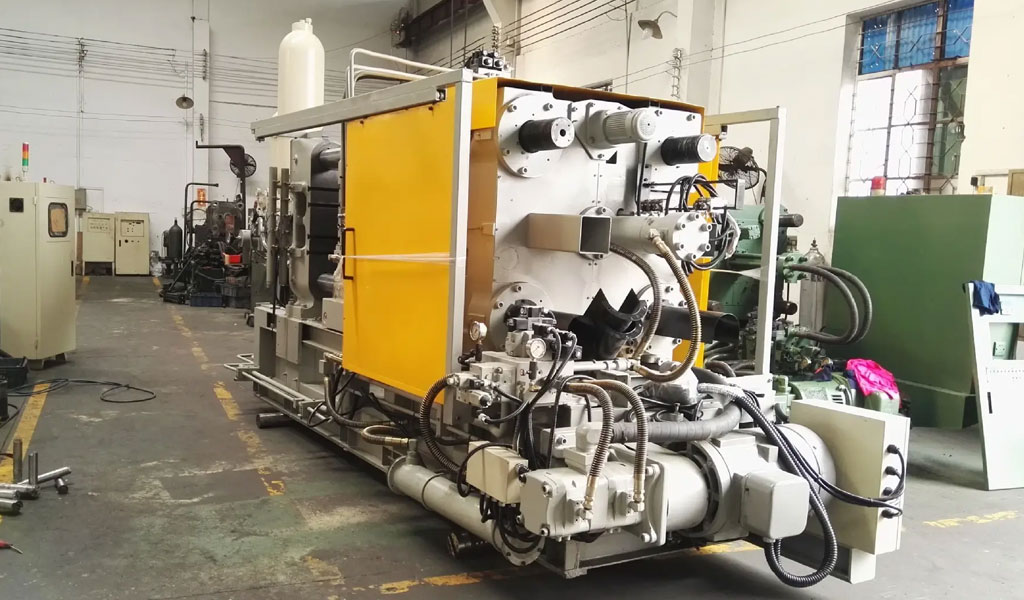

Aluminum Die Casting Services – Custom Aluminum Pressure Die Casting Parts Manufacturer In China

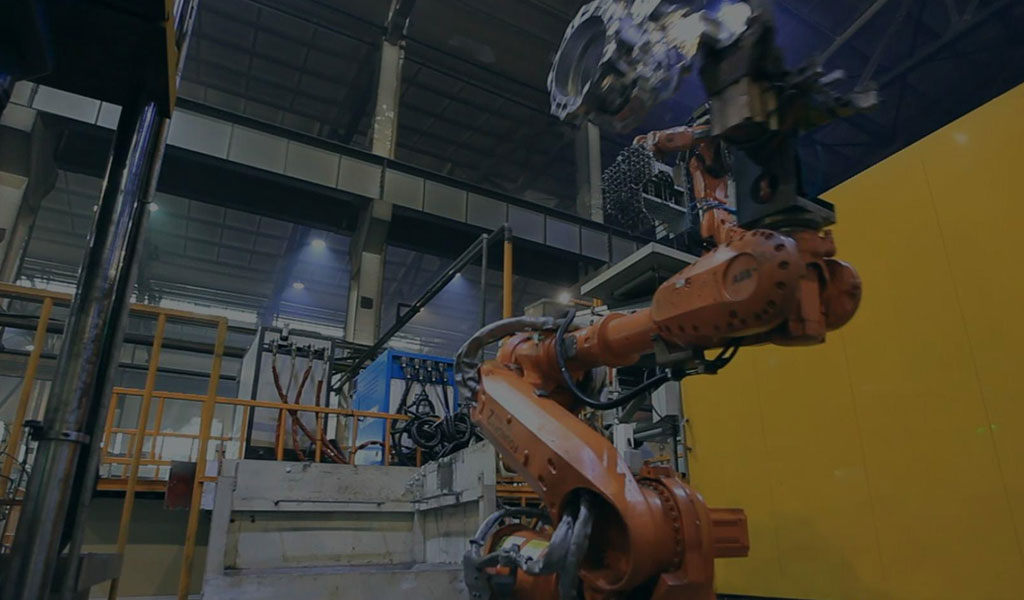

Pintejin Group is experienced in providing a wide range of die casting aluminum services with impeccable quality, reliability, and quick-turn product manufacturing.Pintejin in-house advanced die casting machines(400-3000T Aluminum Die Casting Machine,Brands Include High-End Models Such As Lijin, Yin Zhimi, etc.) ensures unparalleled design and manufacturing capabilities. As a top die casting service provider, we are certified in high volume die casting like aluminum cold chamber die casting, aluminum hot chamber die casting, thin wall die casting and cnc machining die casting parts.With decades of aluminum pressure die casting experience, Pintejin Group’ team of expert designers and engineers can helping every customer innovate and achieve their desired results throughout the entire manufacturing process for every product team. At Pintejin Group, we provide complete high pressure aluminum die casting services. We manage the entire process, from the initial design through machining, finishing, and shipping. Our facility includes an in-house machining center with tolerance capabilities within +/- 0.00025 of an inch. Our additional processes include coatings, annealing, testing, inspecting, and assembly. Contact us today — let’s make new things possible, together.

Aluminum Automotive Die Casting Services

With automation and robots to enhance automobile manufacturing and design, the automotive industry has nowhere to go but up. Die Casting is the most recent automated volume technology that has been used to optimize and accelerate automobile production processes.With the first industry we served being the high-performance new energy automotive market,Pintejin Group often provide OEM parts services for new energy vehicle brands such as Ideal Auto, BYD, and Honglai.. We understand what it takes to remain competitive in the automotive parts manufacturing industry. Automotive die casting parts not only need to conform to stringent engineering standards, but parts must also adhere to strict aesthetic standards.

Many automotive die casting components are sold directly to the consumer, raising expectations for form/fit/function of the parts to exceed stock components. With that understanding, Pintejin creates aluminum automotive die cast parts that speak to the automotive industry’s expectations for high-performance automotive parts.With our roots deeply embedded in the automotive industry, we have created systems around part handling, automated deburring/surface finishing, non-contact dimensional inspection, and QC inspection in relation to standardized aesthetics and components.

What Are Often Using Grades Of Aluminum Die Casting?

Pintejin expert engineers are experienced in working with different grades of aluminum material to cater to aluminum die casting needs. With our expert advisory services, teams can rest assured that their material choice will fulfill all critical requirements.The below are the common grades of aluminum die casting.

- 380 Aluminum. This popular alloy is both versatile and cost-effective.

- 383 Aluminum. This alloy offers a greater workability than aluminum 380, especially for filling dies and molds, though the finished product may have lower toughness.

- 413 Aluminum. The 413 alloy is the most fluid aluminum alloy available, ideal for filling complex molds under pressure without gaps.

- A360 Aluminum.+ Excellent pressure tightness and fluidity.+ High corrosion resistance.+ High strength in elevated temperatures.

- B390 Aluminum.Suitable for internal combustion engine pistons, cylinder bodies for compressors, and brakes.

- A413 Aluminum.+ Excellent pressure tightness.+ Good choice for hydraulic cylinders. + Suitable for die casting intricate components.

Top-notch And Premium Aluminum Alloy Die Casting Products & Parts Gallery

As a professional aluminum die casting manufacturer based in China, Pintejin offers die casting and aluminum components manufacturing. Nevertheless, only skilled and experienced staff operate the machinery. In addition, the factory is managed well by a Israel and Chinese team. And also, thanks to our additional product design and tooling design engineers, we understand the entire process from idea till manufacturing. Even more, we know the characteristics of aluminum and how to die casting it in different ways. In this way, you will benefit from our experience of how to make aluminum die casting parts in the most economical way. As a result, we always offer the best solutions for your die casting product requirements.

Currently, our aluminum die casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, japan, Israel, Singapore, Malaysia, Italy, Poland, Spain,Netherlands, Korea and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Custom china aluminum die casting service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your aluminum die casting project.

Common Applications Of Aluminum Die Casting

A wide variety of industries rely on aluminum for its versatility and compatibility with the die casting process. Some of the most popular applications of aluminum die casting parts include:

- Appliances. Die casting produces identical and interchangeable parts, which is crucial for mass-manufactured consumer appliances.

- Automotive. Aluminum automotive parts are strong and lightweight, which enhances fuel efficiency for automobiles and heavy trucks.

- Electric motors and fluid pump motors. Aluminum has excellent dimensional stability, even at the high temperatures found in motor and pump operation.

- Hand tools. Aluminum tools are lightweight, strong, and easy to handle.

- Hardware (fasteners). Aluminum fasteners withstand corrosion and environmental wear for a long-lasting hold.

- LED lighting. Aluminum components conduct electricity well, contributing to the efficiency to LED lighting.

- Medical/healthcare. Medical devices need to be strong, lightweight, and rigid for easy use by medical professionals.

- Military. Aluminum is a strong, cost-effective material choice for vehicle components, electronics, and structural components.

- Recreational (interior/exterior parts). Aluminum fasteners, grommets, and other hardware are strong, rigid, and resistant to environmental damage.

- Retail scanning. Die casting produces housings and hardware components used in retail scanning equipment.

- Robotic automation. Industrial systems require strong, high-quality aluminum components that can integrate with other hardware.

- Security. Die casting aluminum produces high-precision components for smart locks, security cameras, and other security devices.

- Video conferencing. Precision video conferencing system parts and housings are often produced using die casting.

The Process Flow Of Aluminum Die Casting

The four basic processes of die-casting aluminum industry are annealing, normalizing, quenching and tempering. These four processes are called “four fires” in die-casting. In the process of die-casting, quenching and tempering are closely related. , both are indispensable.

Application of aluminum die castings Aluminum materials and aluminum alloys have good fluidity and plasticity, so various complex and difficult die castings can be made. Castings made of aluminum alloys and metal aluminum have high precision and surface finish. , which greatly reduces the mechanical processing of castings, greatly reduces labor intensity, and saves electricity and metal materials. Because of its high internal quality and external quality, aluminum die castings are widely used in automobile manufacturing, internal combustion engine production, motorcycle manufacturing, motor manufacturing, transmission machinery manufacturing, precision instruments, landscaping, power construction, and other industries. , become the new favorite of die casting industry.

China Top Coating And Finishing Options To Give Your Aluminum Parts A Fresh Look

Pintejin Group offers extended options in coating and finishing to give your parts the look they needed depending upon the requirements of your project. Be it shot blasting, sandblasting, anodizing, polishing, electrophoresis, oxidation, powder coating, or painting we give you all options that suit your need.

- CNC Machining:This is our basic process, and the surface will be deburred and other basic treatments.

- Polishing:Mainly use with polishing wax polishing wheel for processing the surface of aluminum alloy shell, so that we can reduce the roughness on the surface of the aluminum alloy shell, make the surface smooth and light or mirror effect, and can effectively repair aluminum alloy shell surface scratches and scratched.

- Brushed:Brushed is a kind of repair process, because the local has a scratch on the metal surface, on the whole surface with wire drawing machine make consistent scratches (reduce wall thickness), to cover up the scratches.

- Sandblasting:Main effect is cleaning the surface, very high speed to spray the sand on the surface. In front of the oxide sandblasting can increase the surface roughness, reinforced metal feeling at the same time.

- Anodized:Anodized method is the use of electrolytic principle of dc, ac/dc power, in the form a layer of oxide film on the surface of workpiece or products, in order to increase the corrosion resistance and beautiful way.

- More Metal Finlishing Method