Die Casting Mold Material

The Material Of Die Casting Mold

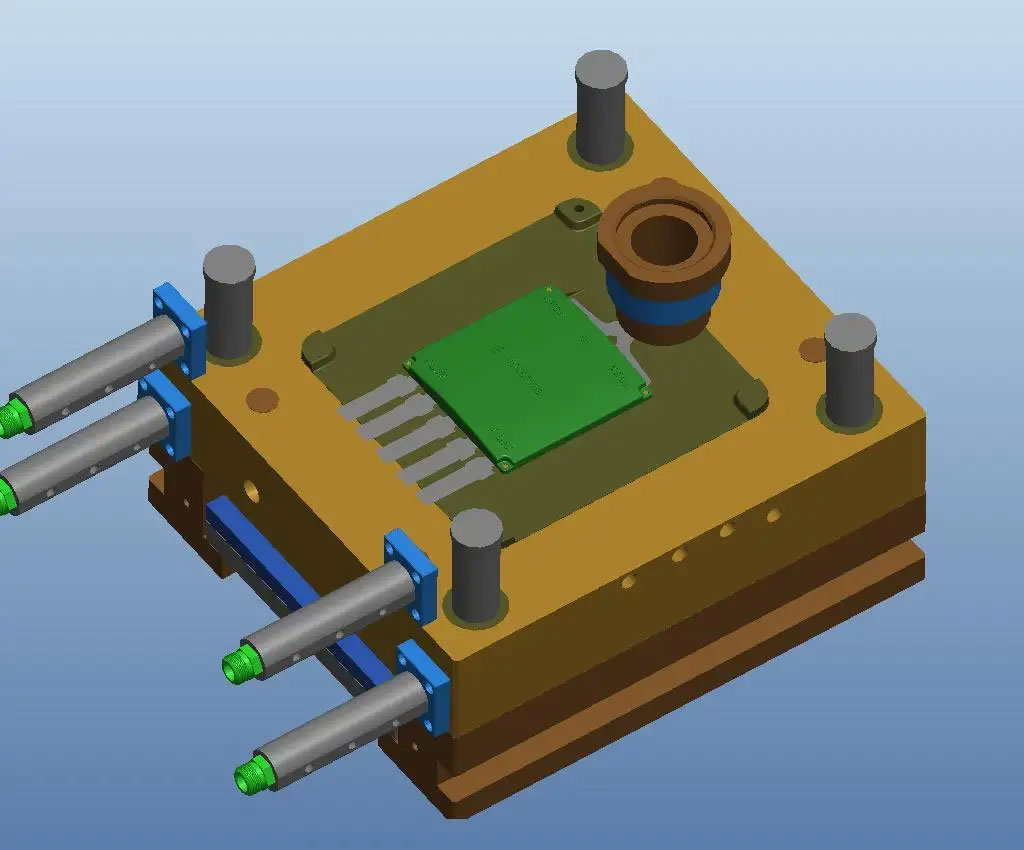

There are lots of mold materials that can be used for making die casting molds for manufacturing metal parts, including aluminum, steel, brass and copper, and many others, The tool steel materials and Mold Steels are some of the common materials in making of die cast molds.

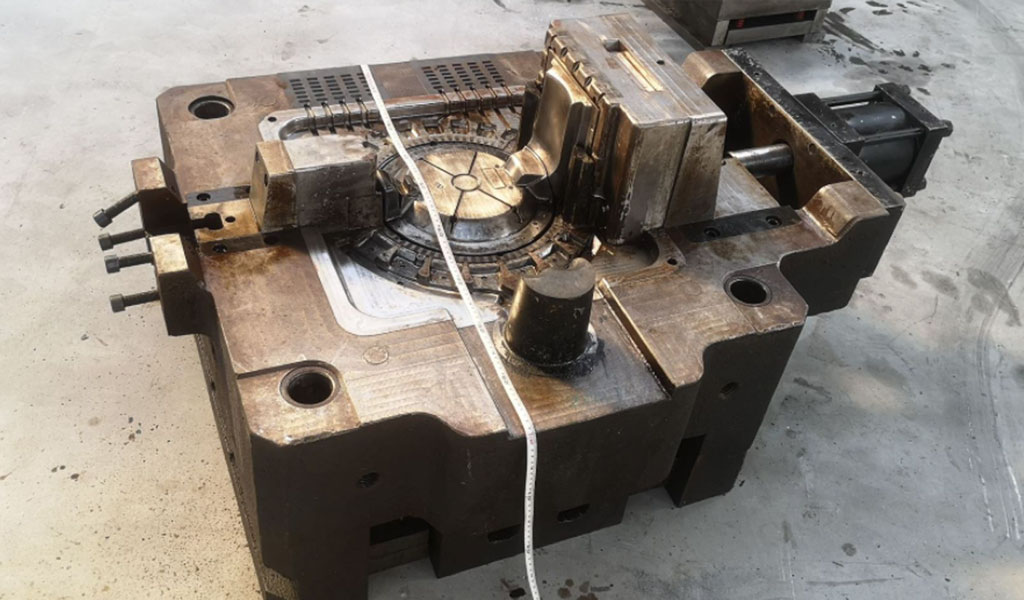

1.2344, 1.2343, S136, H-13. This type of steel is used for cavity and core inserts, this is for the high quality of die casting mold, mold life time can be 1 million shots or more. This is a very high toughness, low-hardness steel used for high quality cavity and core requirements. The hardness of those steel can be hardened to HRC 48-60 degree.

1050 carbon steel. This steel is used for mold bases, blocks, and clamp plates, this steel has 25% greater tensile strength than 1020 and can be easily machined.

P-20, S136H, NAK80, 718H tool steel. Those are pre-hardened steel which has hardness of 28 to 40, which provides moderately high hardness, good machinability. It is used primarily for cavities and cores, as well as stripper plates, mold life-time made in those steel is around 0.5 million shots or more.

Die casting different alloys, the working temperature of the mold is different, and the material requirements are different; the same alloy die casting is used in different places, and its materials are also different. See the table below for details.

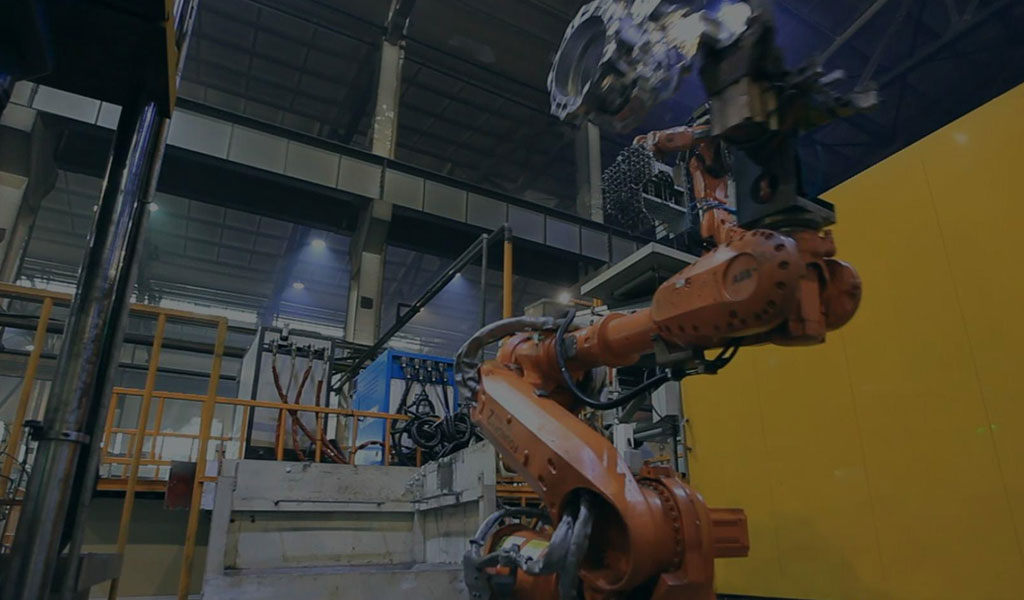

Die-casting die is a method of casting liquid die forging, a process completed on a dedicated die-casting die forging machine. Its basic process is: the molten metal is first cast at low speed or high speed and filled into the cavity of the mold. The mold has a movable cavity surface. It is pressurized and forged with the cooling process of the molten metal, which not only eliminates the shrinkage of the blank. Loose defects also make the internal structure of the blank reach the broken grains in the forged state. The comprehensive mechanical properties of the blank are significantly improved.

Die-casting mold materials can be roughly divided into three categories according to the place of use:

Parts In Contact With Molten Soup

For this reason, the main components of the mold are formed.

Due to the harsh environment and production conditions of the die-casting process, the materials used for this need to have:

- Good Machinability

- Good High Temperature Strength

- High Temperature Hardness

- High Temperature Toughness

- Anti-Tempering

- Stability

- High Temperature Wear Resistance

- Thermal Fatigue Resistance

- Good Hardenability Heat Treatment Dimensional Stability

- Good Thermal Conductivity

- Small Thermal Expansion Coefficient

Sliding Fitting Parts:

- Good Abrasion Resistance And Proper Strength

- Appropriate Hardenability And Small Heat Treatment Deformation Rate

Structural Parts

- The Outer Mold And Fastening Parts Need To Have Sufficient Strength

- There Are Many Types Of Tool Steel,And The Price Is Expensive.

- The Selection Just Now Needs To Consider The Use Environment And Economic Factors.

The table below is a list of commonly used materials listed in References.

a list of commonly used materials listed in References.

Pre-hardened steel (FDAC, P20) is only used for die casting of low-temperature alloys (zinc, tin, aluminum) in small quantities. The rough machining of hot work tool steel (SKD61, H13) needs to be done in the annealed state, and then quenched and tempered (quenched and tempered) before fine machining. The white layer produced by electrical discharge machining needs to be ground off to avoid shortening the life of the mold. High-quality hot work tool steel (premiumgradeH13orSKD61) has a good life due to its homogeneity.

Contact Us About Our Die Casting Molds Services

At Pintejin, we are proud to provide manual and CNC machining, surface finishing, die casting mold development, and other die casting services. Contact Us to learn more about our machining services for die cast parts, or Request a Quote to get your die casting project started today.

Pintejin is your premier manufacturing source for die cast machining since 1995.