Die Casting Mold Cost

The Cost Of Die Cast Molds And Die Casting Products Cost?

Effective die casting can produce thousands of high-quality molded casts in a relatively short amount of time while utilizing a single mold. In order to know what is cost for your die casting project, then you need to get both cost for your die casting mould and casting parts, there are two type of mold cost, one is export mold cost, one is local mold cost plus the die casting parts cost.

The machining process of die-cast parts must be considered well before any order for the tooling is released.A careful evaluation of machined requirements can lead to redesign for net shape die-casting or near-net shape with a reduced number of operations.below we will give your cost guideline to two options.

1. What Is Cost For Export Die Casting Mold

To know the cost of die casting mold there are a few things that you are going to provide to your supplier, in order to make sure that you have given the supplier all of the information that they need to check the price accurately, below are some key points for mold price estimating, this is the most important information for export molds.

- First of all, you need to make sure that you have a 3D part design in your hands, if you do not have the drawing then you need to have the pictures of a sample with approx. part size and show your supplier that part structure.

- Second. You need to know how many die casting times of the mold your requirement, for example. 0.5 million shots of a lifetime or 1 million shots of a lifetime requirement, because those two requirements will cause different price.

- Third. You need to inform them how many cavities you expect for the die casting mold. Because this will affect the mold price as well.

The above items are very import information to quote a mold price for export mold (you will bring the mold back to your country for production) because all of the information will change the mold price.

2. What is the cost for die casting products and local mold price

If you only need die casting parts, then you only need to tell us (or other die casting company) what metals will be and how many parts do you need per time, what is a surface requirement and the colors of the parts, then they will take the rest for you.

To get the cost for your die casting products it is much easy than getting a price for export die casting mold, simple steps as below to get die casting molding service price easy.

- What metals will be? for example aluminum, zinc, magnesium, copper?

- What color do you require for your die casting parts? There are lots of colors, you could take a color reference from pantone color.

- What is the part surface requirement? Texture (graining or matt) or high polishing? Texture code could take reference from VDI3400.

- 3D part design (STP or IGS format file will be great for all of the companies), if you do not have a 3D part design, then send your sample pictures with part size and part weight, or idea picture and explaining to us, we still can get the price for you.

- How many parts do you need per time?

- If have any special function requirement?

With the above information, you will get a mold cost and unit molding cost, that information is important factors to estimate the die casting molding cost. Otherwise, any price will not have any references.

The manufacturing world has been increasingly confusing over the years. If you are in this industry, you probably already have this sense of confusion.

What’s happening is that the global market is really starting to come true. A few years ago, there were a few outsourcing companies in some countries like China, but now it is impossible to track production.

Looking at industries such as die casting molds, you can see that this trend has really begun. However, it may be overwhelming at first, but there is no doubt that productivity will increase significantly.

Today,Die Casting China has become even more efficient due to a faster turnaround.

Welcome to our die casting Mold & Moulding Company.

We offer custom die casting mold & molding services, post manufacturing, electronic contract manufacturing and assembly service, 40% saving for mold manufacturing and molding production services,

We have over 30 years of experience in die casting mold manufacturing services, fluent technical English communication, rich manufacturing experience to handle your project in high quality. Contact us to discuss about your project.

We 100% guarantee your project will be successful. You will be impressed and satisfied with our quality, price, and services. we are willing to share with you some of our customers to let you verify our quality and service.

Send us your requirement for quotation, you will not lose anything but having our competitive price for reference.

To protect your project from copy, We can sign an NDA document to protect your project

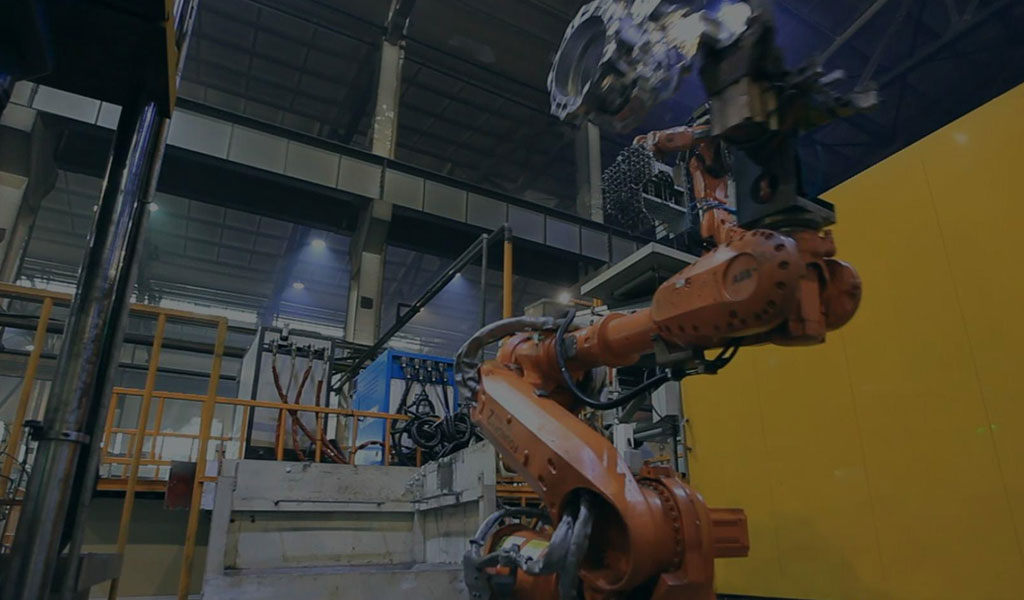

in the following, you will find information about die casting molding processes, techniques, and specialized moulding technology, defects, troubleshooting solutions, below are some of molds we made before.