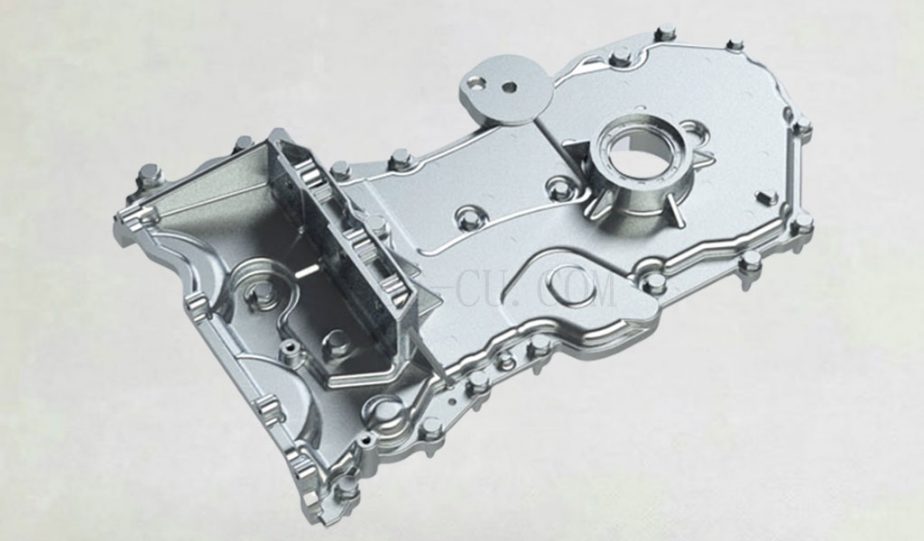

Automotive Engine Front Cover Manufacturing

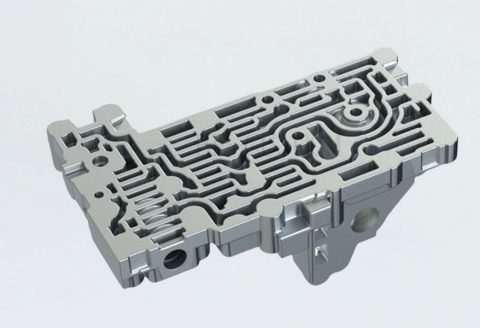

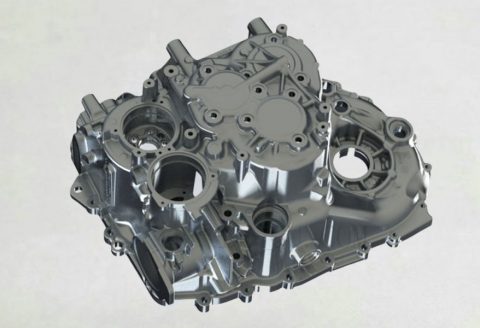

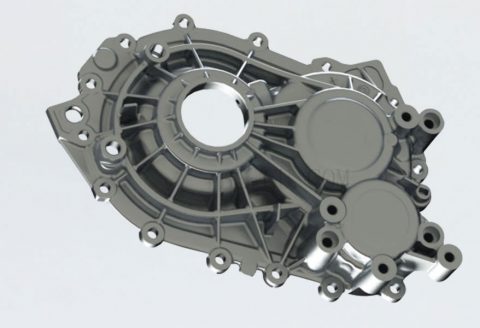

Custom Automotive Engine Front Cover manufacturer of die castings. Works with aluminum and ferrous materials. Features include annealing, enameled, heat treated, thin wall, plastic-coated, anti-static, resistant to abrasion, acid, corrosion and wear. Prototypes and low to high production volume are offered. Serves electronics, electrical, aerospace, automotive, architectural, chemical, HVAC, military, marine, medical, metal or plastic processing, packaging, power generation, nuclear, transportation, wastewater, oil and gas industries. Blanket orders are accepted.

- High-quality metal castings. Cost, quality, and delivery time all matter equally. Get the metal die cast parts you need – when you need them – with Pintejin.

- Discover rigorous, industry-leading quality standards. Stop settling for “okay,” “average,” or “so-so” metal die cast manufacturing. Pintejin delivers best-in-class, ISO:9001 certified die casting. Our multilevel due diligence means we have boots-on-the-ground engineering support to ensure quality at every step.

We do not only save your cost in automotive mold making, but also excellent service & high-quality die casting automotive parts services. We have produced metal die casting parts for companies worldwide.Well, what are you waiting for? Get started on your journey with A mold manufacturer by contacting Pintejin and lets them be your OEM and metal die casting China partner. send an email to [email protected]

Categories: Automotive Die Casting, Die Casting Aluminum, Die Casting Car Engine