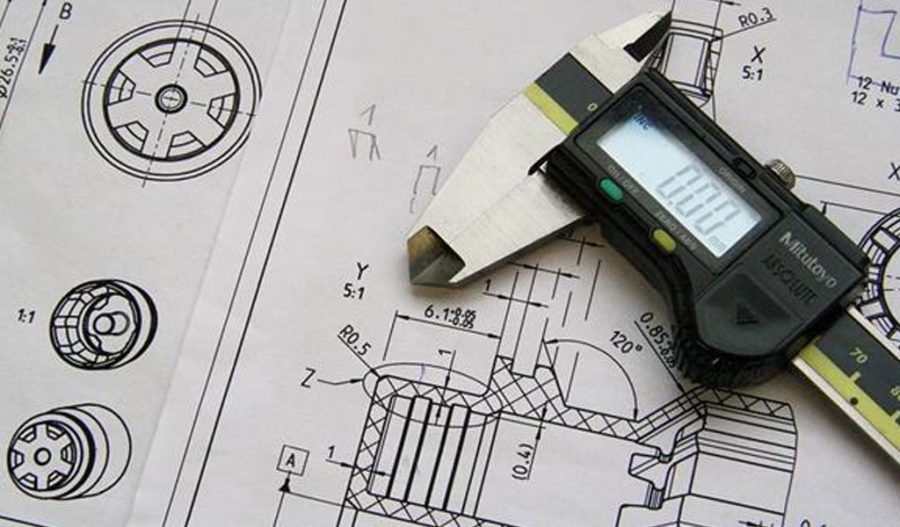

In the intricate world of engineering, precision is paramount, and the foundation of this precision lies in engineering drawings. These drawings serve as a blueprint for the entire manufacturing process, making their accuracy and efficiency crucial. In this comprehensive article, we will delve into the top 10 engineering drawing tips that not only enhance precision but also contribute to significant time and cost savings.

Embrace Digital Tools for Drafting

The advent of digital drafting tools has revolutionized the field of engineering drawing. Utilizing sophisticated software like AutoCAD or SolidWorks allows for quicker iterations, precise measurements, and seamless collaboration among team members. Embracing digital tools is the first step towards an efficient drawing process.

Standardization is Key

Establishing and adhering to standardized drawing practices across projects ensures consistency and reduces the chances of errors. By employing industry-standard symbols, conventions, and templates, engineers can streamline the drafting process, saving time and minimizing costly mistakes.

Leverage Parametric Design

Parametric design enables engineers to create dynamic, interconnected drawings. Changes made to one part of the drawing automatically propagate throughout the entire design, eliminating the need for manual adjustments. This not only accelerates the drafting process but also reduces the risk of oversights.

Efficient Component Libraries

Building and maintaining a comprehensive library of standard components can significantly expedite the drawing process. Reusing standardized elements reduces the time spent recreating common parts, fostering consistency across projects, and ultimately leading to cost savings.

Clear and Concise Documentation

Well-documented engineering drawings are a cornerstone of efficient communication. Providing clear and concise instructions, annotations, and notes on the drawings can prevent misunderstandings, reducing the likelihood of rework and the associated time and cost implications.

Collaborative Design Reviews

Engaging in regular design reviews with team members and stakeholders fosters collaboration and ensures that potential issues are identified early in the process. This proactive approach helps in avoiding costly revisions later in the project timeline.

Implement Design for Manufacturability (DFM) Principles

Incorporating DFM principles during the drawing phase enhances the manufacturability of the designed components. By considering manufacturing constraints and processes upfront, engineers can minimize design iterations, leading to both time and cost savings during production.

Utilize Geometric Dimensioning and Tolerancing (GD&T)

Precision is the essence of engineering drawings, and GD&T provides a standardized language for communicating geometric specifications and tolerances. Implementing GD&T reduces ambiguity, improves accuracy, and contributes to more efficient manufacturing processes.

Invest in Training and Skill Development

A well-trained and skilled workforce is essential for optimizing the engineering drawing process. Investing in ongoing training programs ensures that team members are proficient in the latest tools and techniques, enhancing overall efficiency and reducing the likelihood of errors.

Continuous Improvement through Feedback

Establishing a feedback loop for engineering drawings is crucial for continuous improvement. Actively seeking input from manufacturing teams, incorporating lessons learned from past projects, and implementing feedback-driven enhancements contribute to an iterative and ever-improving drawing process.

Conclusion

In the fast-paced world of engineering, time is money, and precision is non-negotiable. By embracing digital tools, standardizing practices, leveraging parametric design, and implementing other key tips discussed in this article, engineers can not only enhance the efficiency of their drawing processes but also realize significant time and cost savings across projects. As the industry continues to evolve, mastering these drawing tips becomes instrumental in staying ahead and delivering high-quality, cost-effective solutions.