Die-casting aluminum alloy is a common metal casting process, which can fill the mold cavity with aluminum alloy through high pressure and high speed to produce various complex shapes and high-precision parts. Die-casting aluminum alloys are widely used in automobiles, electronics, aerospace and other fields, and are one of the main methods for manufacturing aluminum alloy parts.

The process of die casting aluminum alloy requires the following steps:

- Melting Aluminum: A block of aluminum is placed in a melting furnace and heated to melt it into a liquid state. In this process, it is necessary to control the melting temperature of aluminum, which is generally controlled at about 750°C. At the same time, in order to obtain a better die-casting effect, a certain amount of alloying elements can be added, such as Mg, Si, etc.

- Adding alloying elements: Add appropriate amount of alloying elements into the molten aluminum as needed to obtain the desired grade of aluminum alloy. The addition of alloying elements can improve the mechanical properties and electrical conductivity of aluminum alloys.

- Degassing and slag removal: improve the quality of molten aluminum by removing gases and impurities in molten aluminum. This process usually uses vacuum degassing technology to remove the gas and impurities in the molten aluminum.

- Mold preparation: Preheat the mold and spray the release agent to facilitate demoulding and prolong the life of the mold. The mold is the key equipment for die-casting aluminum alloy. It is necessary to select the appropriate material and processing technology to ensure the precision and quality of the mold.

- Filling the mold: The aluminum liquid is injected into the mold cavity through the gate to fill the entire cavity. In this process, it is necessary to control the temperature of the aluminum liquid and the flow rate of the gate to ensure that the aluminum liquid can evenly fill the cavity.

- Die-casting: Apply high pressure in the mold cavity to make the molten aluminum solidify and form quickly. In this process, it is necessary to control the size of the pressure and the speed of the injection to obtain a better die-casting effect.

- Demoulding: When the aluminum alloy part reaches a certain temperature, it is taken out of the mold for subsequent processing or direct use. In this process, the temperature and timing of demoulding need to be controlled to ensure the integrity and precision of the parts.

In the process of die-casting aluminum alloy, the following points need to be paid attention to:

Control the injection speed: If the injection speed is too fast, it may cause problems such as aluminum liquid splashing or mold foam, and if it is too slow, it will affect the filling effect of aluminum alloy parts.

Control mold temperature: Too high or too low mold temperature will affect the quality and precision of aluminum alloy parts. Therefore, it is necessary to select the appropriate mold temperature and adjust it according to the actual situation.

Control the temperature of molten aluminum: If the temperature of molten aluminum is too high, it may cause problems such as mold burnout or molten aluminum oxidation, and if the temperature is too low, it will affect the forming effect of aluminum alloy parts. Therefore, it is necessary to control the temperature of the molten aluminum and adjust it according to the actual situation.

Pay attention to mold maintenance: molds are key equipment for die-casting aluminum alloys and require regular maintenance and maintenance to prolong their service life and ensure the accuracy and quality of parts. Therefore, it is necessary to regularly check the wear and damage of the mold, and repair or replace it in time.

In short, die-casting aluminum alloy is a complicated process, which requires certain process technology and operation skills. Only by continuously accumulating experience and learning in actual operation can high-quality aluminum alloy parts be produced. At the same time, in order to obtain a better die-casting effect, it is necessary to pay attention to the above points, and take corresponding measures to control and adjust.

The Classification Of Die Casting Molds

Aluminum alloy die-casting molds can be divided into the following types according to structure, material and die-casting method:

- According to the different die-casting machines used, it can be divided into: horizontal cold chamber, horizontal hot chamber and die-casting mold for full vertical die-casting machine.

- According to the different die-casting alloy materials, it can be divided into: aluminum alloy, zinc alloy, magnesium alloy, copper alloy die-casting mold.

- According to different die-casting methods, it can be divided into: high-pressure die-casting mold, low-pressure die-casting mold, etc.

- According to different mold structures, it can be divided into: two-platen mold, three-platen mold, etc.

- According to the position of the gate, it can be divided into: eccentric gate die-casting mold and central gate die-casting mold.

- According to different core-pulling methods, it can be divided into: die-casting mold with side core-pulling and non-side core-pulling.

- According to the different product structure, it can be divided into: flat plate type, deep cavity type, special-shaped complex structure type die-casting mold, etc.

Working Principle Of Die Casting Mold

During die-casting production, the die-casting mold is installed on the die-casting machine and is integrated with the die-casting machine. Through the pressure of the die-casting machine, the molten metal fills the mold cavity at high pressure and high speed, and the molten metal cools in the cavity of the mold under high pressure. Solidify and form to obtain die castings.

The aluminum alloy die casting mold is mainly composed of a fixed mold and a moving mold. The fixed mold is fixed on the fixed mold mounting plate of the die-casting machine, and the sprue on the fixed mold is connected with the nozzle or pressure chamber of the die-casting machine. The movable mold is fixed on the die-casting motorized mold mounting plate, and moves with the die-casting motorized template to complete the mold opening and closing actions.

The work of the die-casting mold is a periodic work process. When closing the mold, the mold is closed to form the cavity, pouring system and overflow exhaust system, and the liquid metal fills the cavity under high pressure and solidifies. When the mold is opened, the movable mold and the fixed mold are separated, and the casting is ejected under the action of the ejector mechanism.

No matter what kind of die-casting mold, its working process includes the following actions: We will illustrate the working process of a die-casting mold for a certain product:

- Mold closing: the mold is closed and waiting for pouring.

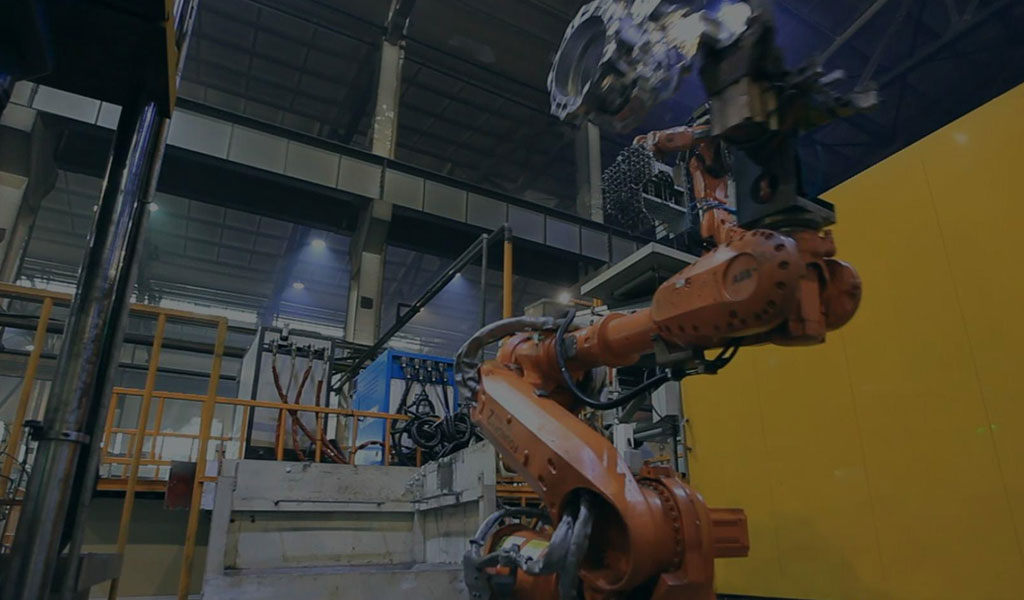

- Filling: The manipulator or the operator beats the material from the furnace and pours it into the barrel.

- Injection: Injection is carried out according to the set process parameters.

- Mold opening: The mold is opened, and the core is pulled with the inclined guide column, and the core is pulled synchronously.

- Core pulling: Under the action of the core pulling device, the mold exits from the side to facilitate ejection; if it is a front (fixed) mold core pulling, it is necessary to pull the core first and then open the mold.

- Top piece: Under the action of the push-out mechanism, the casting is pushed out for easy removal.

- Pick-up: Remove the casting from the mold manually or automatically; if there is a pin, pay attention to the direction and angle, and do not knock or pull it brutally, otherwise the ejector pin will be easily damaged.

- Spraying: Clean the mold cavity, spray the release agent evenly on the front and rear molds.

- First reset mechanism: If there is a thimble under the core puller, it is necessary to make a first reset mechanism such as a pull rod to protect the mold.

- Clamp the mold again and repeat the above process.