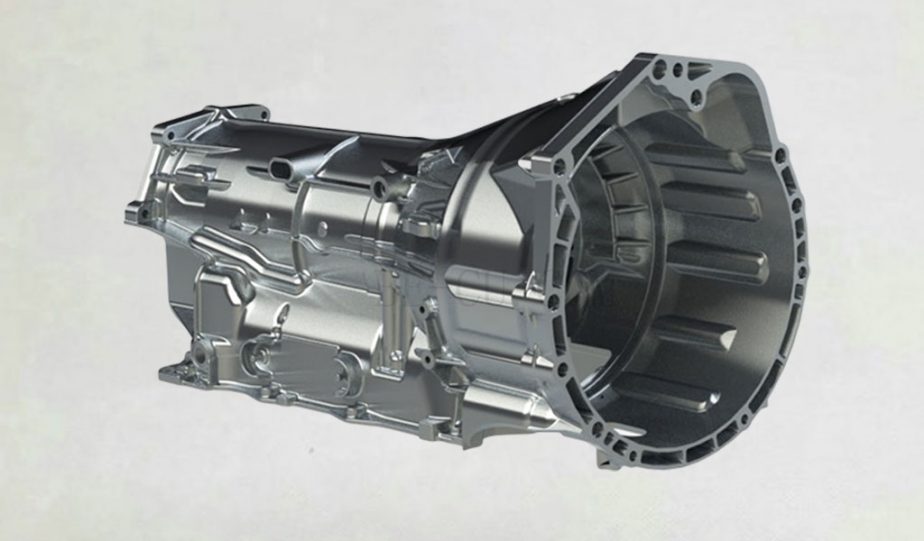

Aluminum Die Casting Gearbox Cavity

Custom Gearbox Cavity precision die casting services. Castings can be manufactured with high tensile strength, thin wall and corrosion, heat, abrasion, stress, acid and wear resistant characteristics. Secondary processes include cleaning, normalizing, quenching, tempering, CNC machining, stamping, tooling, heat treatment, annealing, assembly, engineering, finishing, inspection, e-coating, heat treatment, layout, machining, painting, pattern repair, mounting, gating, rigging, welding, shot blasting, polishing and metallurgical testing.

Capable of casting parts up to 120 inches L x 120 inches W x 20 inches H dimensions (3000 x 3000 x 500mm) with weight up to 500 pounds (250 kilograms). Manufactures to a tolerance of +/- 0.005 inches (0.127 mm). Serving many different industries with offshore contract manufacturing, automation, OEM/ODM, engineering, product development, prototyping, pilot production, quality assurance and supply chain management services. Meets ASTM, ANSI, D2000, REACH, NSF, ISO, RoHS, WEEE and IPC 1752-1, AS9100D, UL, TUV, NSF and others, as required.

We do not only save your cost in automotive mold making, but also excellent service & high-quality die casting automotive parts services. We have produced metal die casting parts for companies worldwide.Well, what are you waiting for? Get started on your journey with A mold manufacturer by contacting Pintejin and lets them be your OEM and metal die casting China partner. send an email to [email protected]

Categories: Automotive Die Casting, Die Casting Aluminum, Die Casting Gearbox