Because of the operation of aluminum alloy casting process will have a larger crystal organization, and in the casting time it is necessary to have a longer time to carry out heat treatment and tempering of these crystal organizations, so as to ensure that the manufactured products are more ideal, however, because it is melting the correct and Surface Treatment when the temperature is closer to the low melting point crystal melting point, therefore, in carrying out the correct treatment of aluminum alloy casting heating Therefore, when carrying out the correct treatment of aluminum alloy casting heating, it is necessary to select a heating furnace and related instruments that are easier to adjust the temperature to carry out monitoring and suitable adjustment of the temperature, and only in this way can we ensure better results of aluminum alloy casting parts.

So, is the heat treatment method selected the same in all cases and characteristics and processing requirements of aluminum alloy casting heat treatment? In fact, not, because in the operation of aluminum alloy casting, the chemical composition of the aluminum parts is different, therefore, when carrying out heat treatment, it is naturally necessary to combine the specific composition to select the appropriate heat treatment method, and there will be certain differences in the reinforcement of aluminum alloy casting, so it is recommended that we should combine the situation when carrying out heat treatment of castings to select the correct correct treatment method.

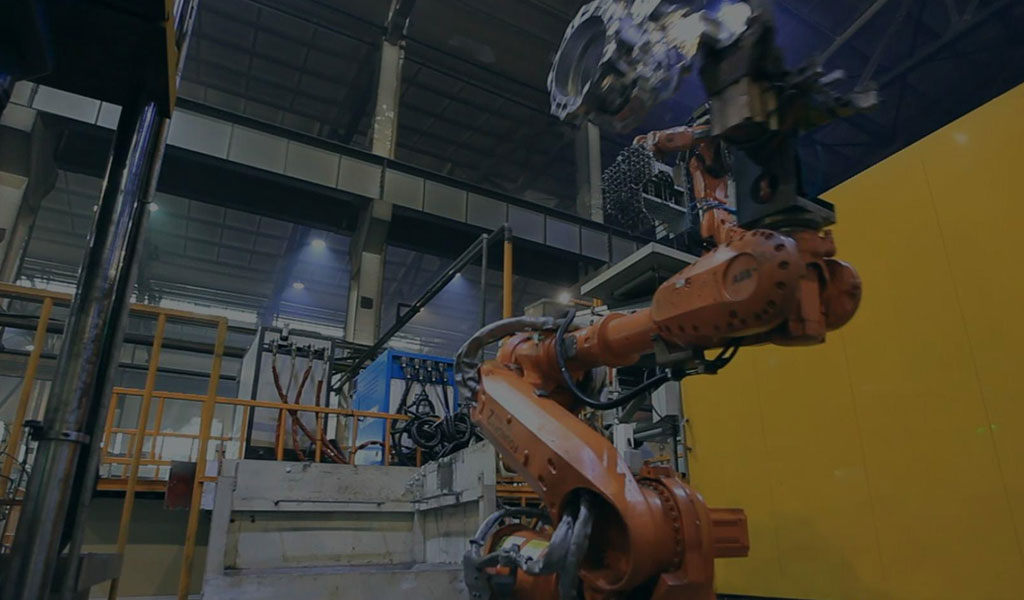

Aluminum alloy casting heat treatment is widely used in the production of castings in various industries, it is more efficient, better quality of castings, and very convenient for mechanized production. In order to ensure that the castings can better meet the needs of use, it is a certain requirement.

- Ensure the correctness of the pouring system and riser to ensure that the aluminum alloy casting process meets the corresponding requirements.

- Good shape, size and quality of the casting are in line with the technical requirements.

- Good exhaust performance of aluminum alloy casting, and the metal type should be easy to take out and repair the installation of the casting.

- The structure should be as simple as possible, convenient for processing and manufacturing, from cost reduction, convenient mechanization, automation, improve production efficiency and labor conditions.

- Aluminum Alloy Casting can ensure the working temperature for a long time in use, and there will be no warping and deformation phenomenon.