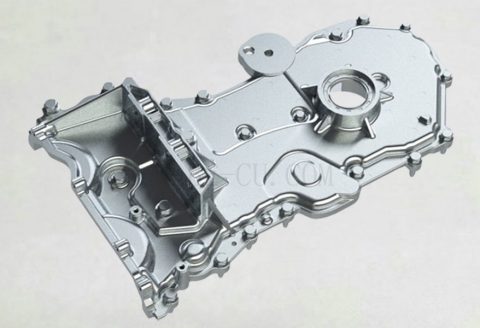

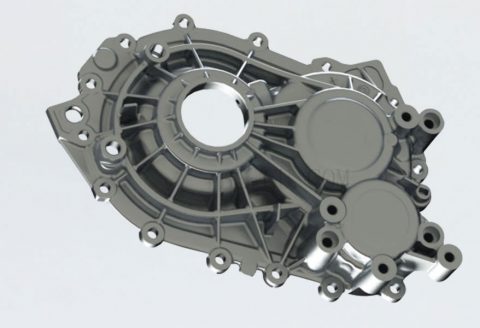

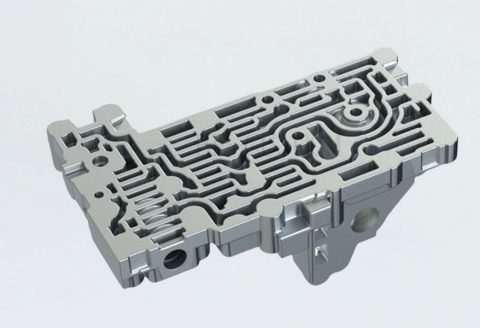

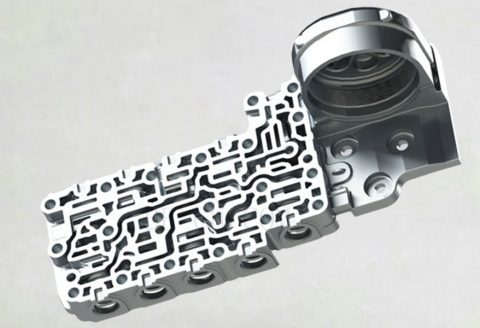

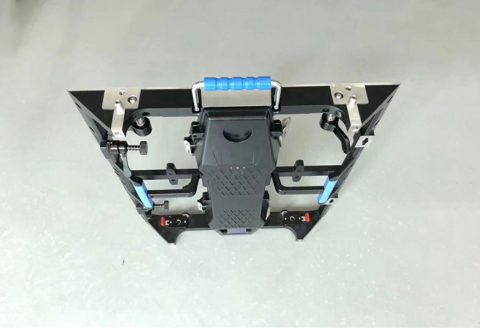

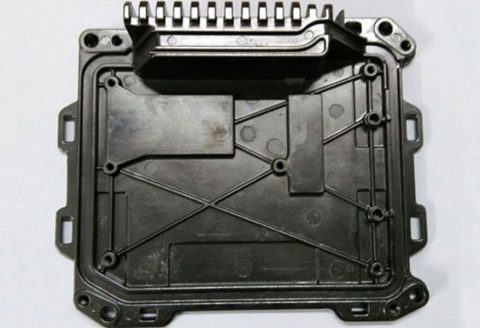

Die Casting Aluminum

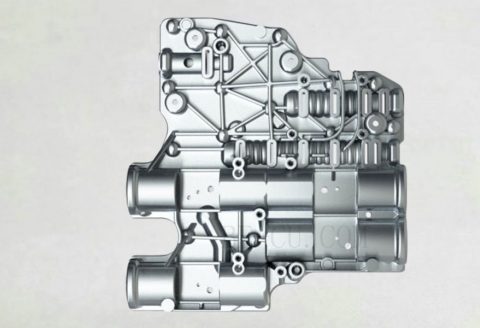

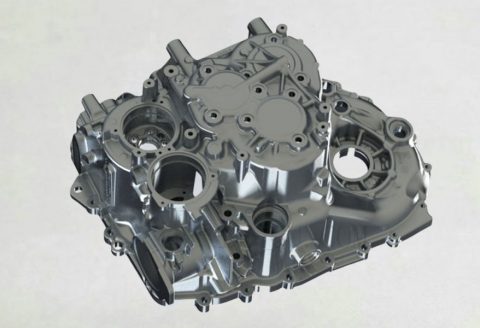

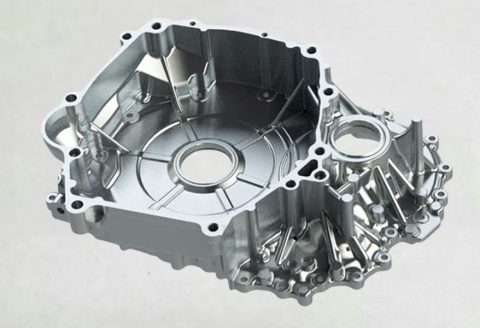

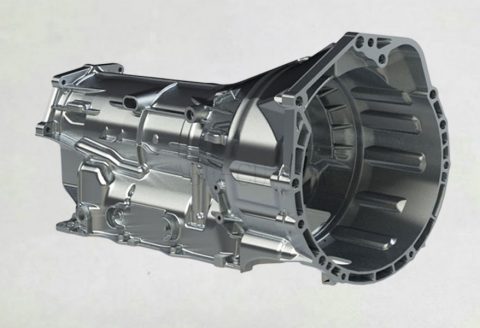

Aluminum die casting alloys are lightweight and possess high dimensional stability for complex part geometries and thin walls. Aluminum withstands good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting. Low-density aluminum metals are essential to the die casting industry. The Aluminum Die Casting process retains a durable strength at very high temperatures, requiring the use of cold chamber machines. The molten metal is still contained in an open holding pot which is placed into a furnace, where it is melted to the necessary temperature. The open holding pot is kept separate from the die casting machine and the molten metal is ladled from the pot for each casting because these high temperatures would damage the normal pumping system. The pressure requirements for cold chamber castings are typically higher than those of hot chamber die castings.

– A manufacturing process that produces accurately, defined, smooth and textured-surfaced metal parts

– Accomplished by forcing molten metals into a mold form due to high-pressure systems

– Corrosion resistant

– Highly conductive

– Have a good stiffness and strength-to-weight ratio

– Based on rapid production

– Allows a high volume of die casting parts to be produced very quickly

– Is more cost-effective than alternative casting processes

Pintejin provides superior quality aluminum die casting parts and components for a wide range of industries including automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others.Aluminum die casting is a great choice for manufacturing parts with the highly valued combination of light weight and superior strength at a high rate. With die casting machines ranging from 80 up to 3,000 metric tons and CNC machine centers, we can produce aluminum die casting parts from a few grams to more than 40 pounds with superior quality ready for assembly. For aluminum die casting parts with requirements of esthetical, functional, or protective coatings, we also offer a broad range of surface finishing including powder coating, e-coating, shot blasting, chrome plating, and bright finish.